The essence of our business lies in nature. Everything began with the forests, the source of our main raw material: wood. Our respect and love for the forests is reflected in a major milestone achieved in 2023, when we obtained FSC certification, recognized internationally.

The Forest Stewardship Council® (FSC®) is an independent, nonprofit, nongovernmental organization created to support environmentally appropriate, socially beneficial, and economically viable forest management worldwide.

FSC’s vision is that the world’s forests should meet the social, ecological, and economic rights and needs of the present generation without compromising those of future generations. (Source: FSC-STD-40-004 V3-1 PT)

We understand that the responsible management of forests is essential for animals to live safely and for surrounding communities and workers who depend on these resources to be respected. By preserving forests, we also preserve rivers and the life that depends on them. Almost everything we need in our daily lives comes from forests!

Chain-of-Custody certification is one of the core components of FSC and assesses product traceability from the forest-based raw material all the way to the final product that reaches the consumer’s home.

Grupo K1 understands that for people to live in the home of their dreams, a healthy environment is essential, which includes the responsibility of companies to minimize their environmental impacts. Therefore, in addition to adopting numerous actions to reduce the impacts of the production process, the Group also directs efforts toward the management of its solid waste.

This requires special attention, since poor waste management can cause soil and water contamination, air pollution, and even visual pollution. Moreover, depending on the type of waste, it can pose risks to human health.

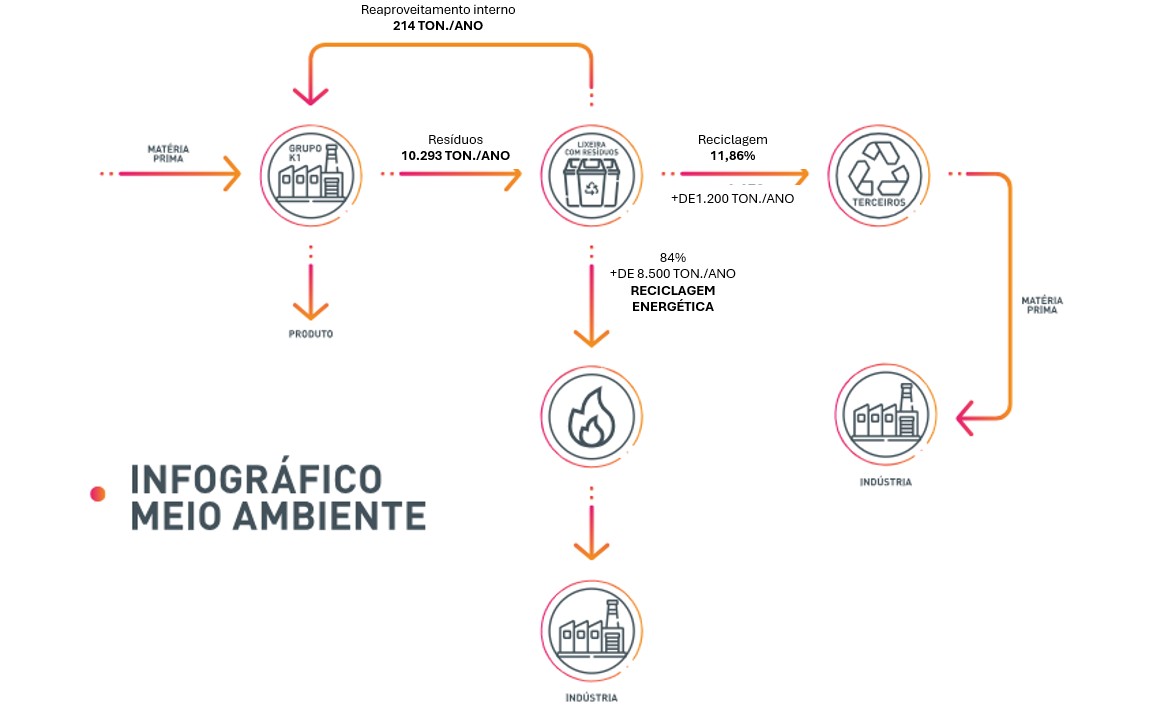

Grupo K1 develops and implements actions that help minimize industrial waste and ensure the proper disposal of the waste that is still generated, always with responsibility toward the environment and people. Proof of this is that in 2024, approximately 10,293 tons of waste were generated. Of this total, 11.86% was sent for material recycling and 84% for energy recycling.

Energy recycling is a highly valuable form of recycling, as it transforms waste into energy for other production processes. At Grupo K1, this type of recycling is conducted by using wood scraps as an energy source in ceramic furnaces. In addition, part of the waste is sent for co-processing. In co-processing, the energy released during the burning of certain waste materials is used as fuel in cement kilns. In other words, the cement industry replaces petroleum coke with waste that has compatible calorific value. Grupo K1 sent more than 172 tons of waste for co-processing, contributing to circular economy practices and reducing the consumption of fossil fuels that generate greenhouse gases responsible for climate change.

Another form of recycling, material recycling, involves transforming discarded products into raw materials to be used either within the process itself or in another industry. In this category, Grupo K1 sent paper, cardboard, plastic, metal, glass, and other materials for recycling, totaling 1,220 tons in 2024, of which 214 tons were reused in the company's own production process.

By sending plastic waste for recycling, the company avoided the consumption of 2,800,000 liters of water, 1,600 MWh of electricity, and prevented 227 tons of CO₂eq from being emitted into the atmosphere. In other words, recycling reduces the amount of waste in the environment, prevents the extraction of new natural resources, and avoids the emission of greenhouse gases. The environmental and economic benefits are significant.

Grupo K1 understands the importance and necessity of solid waste management and assumes the responsibility of ensuring proper disposal. Good waste management not only contributes to the environment and society but also reflects the company's seriousness in addressing environmental issues and its pursuit of sustainability in its operations, generating value for its customers and for society as a whole. Because we understand that caring for the environment is caring for people, we continue working and reinventing ourselves so that you can live in the home of your dreams.

Grupo K1 continuously carries out awareness initiatives with its employees, addressing topics such as reducing water and energy consumption, proper waste disposal and recycling, and biodiversity conservation through lectures, meetings, and digital communication channels.

In June, in celebration of Environment Week, several activities are held to promote awareness among our employees, who act as multipliers within the community. It is considered a special month within Grupo K1’s annual event calendar.

The environmental education we promote within the Grupo K1 community also reaches households throughout Brazil. Our product packaging includes a QR Code through which customers can access information on the proper disposal of generated waste, encouraging recycling.

The company is currently certified by INMETRO for the manufacturing processes of mattresses and monobloc plastic chairs. INMETRO certification has as its main goals the standardization of manufacturing processes and the promotion of a culture of continuous improvement within the company. This certification ensures that products comply with all current standards and regulations, guarantees full traceability of the entire production process, and provides consumers with a perception of quality and reliability. In addition, it strengthens brand reputation and increases the company's potential to attract new customers in the market.

We also hold the OEA (Authorized Economic Operator) certification, which aims primarily to combat serious customs violations such as international drug trafficking and terrorism, thereby promoting greater security and reliability across the global logistics chain. Participation in the program brings strategic benefits, such as reduced storage costs at customs facilities and the ability to work with clients who require OEA-certified partners. Additionally, companies recognized by the Federal Revenue Service as low-risk operators receive significant commercial advantages, including priority in cargo clearance, fewer customs inspections, and greater agility in foreign trade operations, ensuring speed and competitiveness in international business.

The company is currently certified by INMETRO for the manufacturing processes of mattresses and monobloc plastic chairs. INMETRO certification has as its main goals the standardization of manufacturing processes and the promotion of a culture of continuous improvement within the company. This certification ensures that products comply with all current standards and regulations, guarantees full traceability of the entire production process, and provides consumers with a perception of quality and reliability. In addition, it strengthens brand reputation and increases the company's potential to attract new customers in the market.

We also hold the OEA (Authorized Economic Operator) certification, which aims primarily to combat serious customs violations such as international drug trafficking and terrorism, thereby promoting greater security and reliability across the global logistics chain. Participation in the program brings strategic benefits, such as reduced storage costs at customs facilities and the ability to work with clients who require OEA-certified partners. Additionally, companies recognized by the Federal Revenue Service as low-risk operators receive significant commercial advantages, including priority in cargo clearance, fewer customs inspections, and greater agility in foreign trade operations, ensuring speed and competitiveness in international business.

The manufacturing activities carried out at Grupo K1 comply with all municipal, state, and federal legal requirements. Furthermore, every two years, all requirements demanded by the environmental agency for the operation of the facility are audited by a third party and reported to FEPAM, ensuring full transparency regarding the legal compliance of our operations and reinforcing our reliability.

Our practices go far beyond what legislation requires. A multidisciplinary team is responsible for our environmental management, and it is precisely the different educational backgrounds and the diversity of positions held by each team member that contribute to the continuous improvement of our processes. We focus on maximizing the use of raw materials, water, and energy. Through internal and periodic audits, we ensure the effectiveness of our actions.

Whenever waste must be disposed of, the environmental compliance of the receiving facilities is verified.

In addition, the companies responsible for waste collection undergo a thorough assessment to ensure compliance with laws and standards related to the transportation of hazardous waste.

Objetivos do Desenvolvimento Sustentável (ODS)

Objetivos do Desenvolvimento Sustentável (ODS)